Loading...

Who We Are

Greco Cleaning Systems, Inc. supplies ultrasonic cleaners, rinse tanks, rinse water deionizers, hot air parts dryers, and centrifugal dryers to the medical, 3-D post processing, electronic, precision machining, defense, and metal finishing industries; offering solutions to nearly any cleaning problem. All of our cleaning and drying equipment is designed and built in the United States, meeting the highest quality standards. Our equipment is widely known for its quality, durability and ease of use. We pride ourselves on our technical assistance and customer service, before, during, and after the sale.

History

In 1945, seven brothers were returning from serving their country in World War II. They found themselves looking for work at a time when the textile industry was leaving the Providence, Rhode Island and Southern Massachusetts, and relocating in the South. They discovered however, that the local jewelry plating industry was beginning to fill the void and was in need of a good source for plating tanks. At that time, plating tanks were constructed from wood and lined with tar, which was used as a sealant. After determining that the jewelry plating market had potential for a promising future, the brothers assembled a woodworking shop in their mother's basement, and began building tanks and lining them with tar. Greco Brothers Incorporated was born.

It was soon necessary to expand into more suitable facilities. In the early 1950's, Greco Brothers introduced their burnishing tumbler. New construction materials were eventually available for building plating tanks, as were more technologically-advanced control systems. Greco Brothers manufactured plating tanks throughout the 1950's and 1960's and began offering complete turn-key plating room installations.

Greco Brothers continued building plating tanks throughout the 1970's, fabricating them from stainless steel, fiberglass, and polypropylene. We also provided plating rectifiers, filter systems, ultrasonic cleaners, and vapor degreasers to the enormous number of jewelry platers in the region. With the introduction of new EPA regulations, Greco Brothers began designing and building waste treatment systems to neutralize the effluent stream of their customers' plating operations. We continued to supply burnishing equipment in the form of tumblers and mass-finishing vibrators. At the peak of the jewelry plating industry, there were 1,200 plating companies within 50 miles of the Greco Brothers factory. In the mid 1970's Greco Brothers diversified into the part-cleaning industry.

By the early 1980's our line of cleaning equipment had expanded to include ultrasonic cleaners, rinse purifiers, hot air dryers, centrifugal dryers, and vapor degreasers. This equipment was marketed under the Greco Brothers name, as well as private-labeled for other equipment suppliers. Our customer base grew to include manufacturers in the medical, electronic, precison machining, defense, and metal finishing industries. In addition to being known for plating equipment, the Greco name soon became synonymous with quality cleaning and drying equipment.

In the early 1990's, due to a perfect storm of environmental regulations, the rise in the price of gold, and changes in popular fashion, the local jewelry plating industry began a cataclysmic decline. By the mid 1990's it had become a mere shadow of its former self. The number of local plating companies was diminishing quickly; from over 1,200 in early 1970's to less than 100 by 1992. Greco Brothers' cleaning equipment business was growing quickly, but not nearly fast enough to make up for the loss of plating equipment sales resulting from the catastrophic decline in the jewelry plating industry.

To compensate for the loss of this previously-enormous customer base, we decided to take advantage of our expertise in stainless steel fabrication. A custom-fabrication service was developed. Our custom-fabrication service produced nearly any weldment that could be built from stainless steel. We built custom-designed benches, cabinets, frames, tanks, pans, heating coils, and nearly any stainless steel product that our customers requested - all while continuing to grow our cleaning equipment business.

Around 2010 however, it was determined that the time required to engineer and build these custom products would be better spent on the company's primary area of expertise - cleaning equipment. So, we began to scale back our promotion of custom weldments and to concentrate more resources on the development and improvement of our line of cleaning and drying equipment.

In 2017, Greco Cleaning Systems was formed to pave the way for a separation of our custom-weldment division and out cleaning equipment division. In 2018, the custom fabrication portion of the business was sold and Greco Cleaning Systems began operations in our new facility in Warwick, RI. From that facility, we now offer the complete line of cleaning and drying equipment formerly offered by Greco Brothers and pride ourselves in maintaining the high standards of quality that Greco Brothers' equipment was famous for.

Today, Greco Cleaning Systems is proud to provide state-of-the-art, high-quality cleaning and drying equipment to an ever-growing variety of industries worldwide. We also serve as a master distributor and service center for New Holland Dryers and for Branson ultrasonic cleaners. And we continue to provide technical assistance, parts, and service for all the products previously built and marketed by Greco Brothers.

1945

Lining wooden plating tanks with tar

1975

Plating facility filled with Greco Plating Tanks

1995

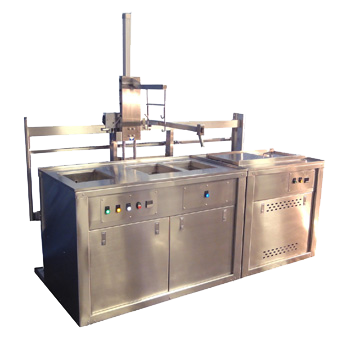

Custom-designed ultrasonic cleaner

2015

Automated Programmable Cleaning Bench