Loading...

In addition to the Hot Air Convection Dryers that we manufacture, Greco Cleaning Systems is pleased to offer industrial Centrifugal Dryers through a special arrangement with Ford New Holland. Centrifugal dryers are most appropriate for small parts being processed in bulk. Due to the close proximity of the parts and resistance they offer to free air flow, these applications often present challenges to normal convection dryers. Centrifugal drying overcomes those obstacles and speeds up production by drying two ways. Centrifugal force from the spinning action of the basket "throws off" excess water, oils, or other liquids. At the same time, a turbine fan mounted below the basket creates a powerful suction that pulls heated air through the parts load for added drying power.

This double-drying action assures fast drying and reduces the scarring and marring frequently responsible for costly rejects. In most cases, producing spot-free, moisture-free parts in under 60 seconds.

Each of these centrifugal dryers is also available in a chipwringer version. Chipwringers are designed for use with oil applications. They spin excess oil from the surface of the parts and direct it to a drain pipe for collection. Chipwringers are intended to operate at room temperature and are not configured with heat.

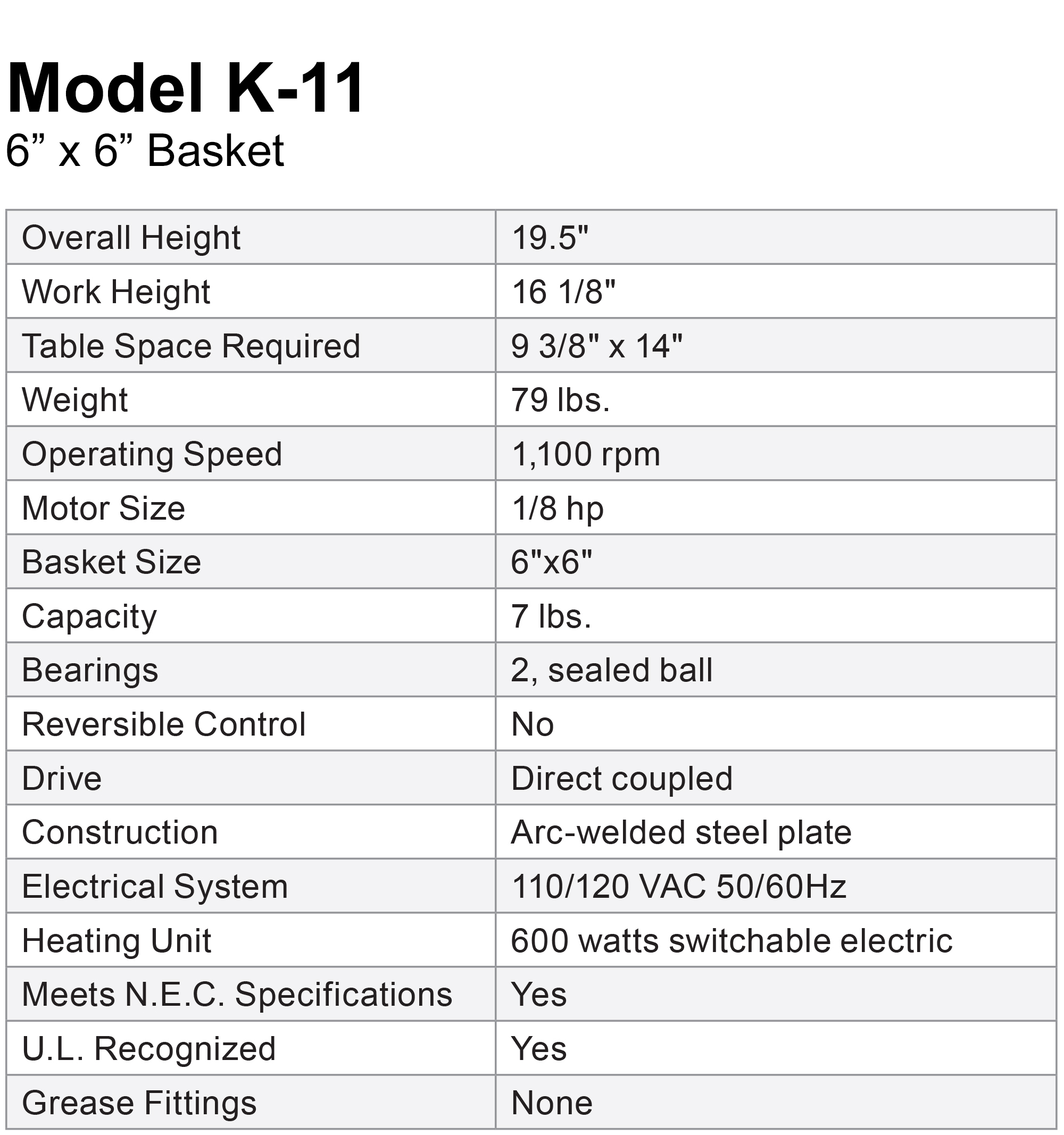

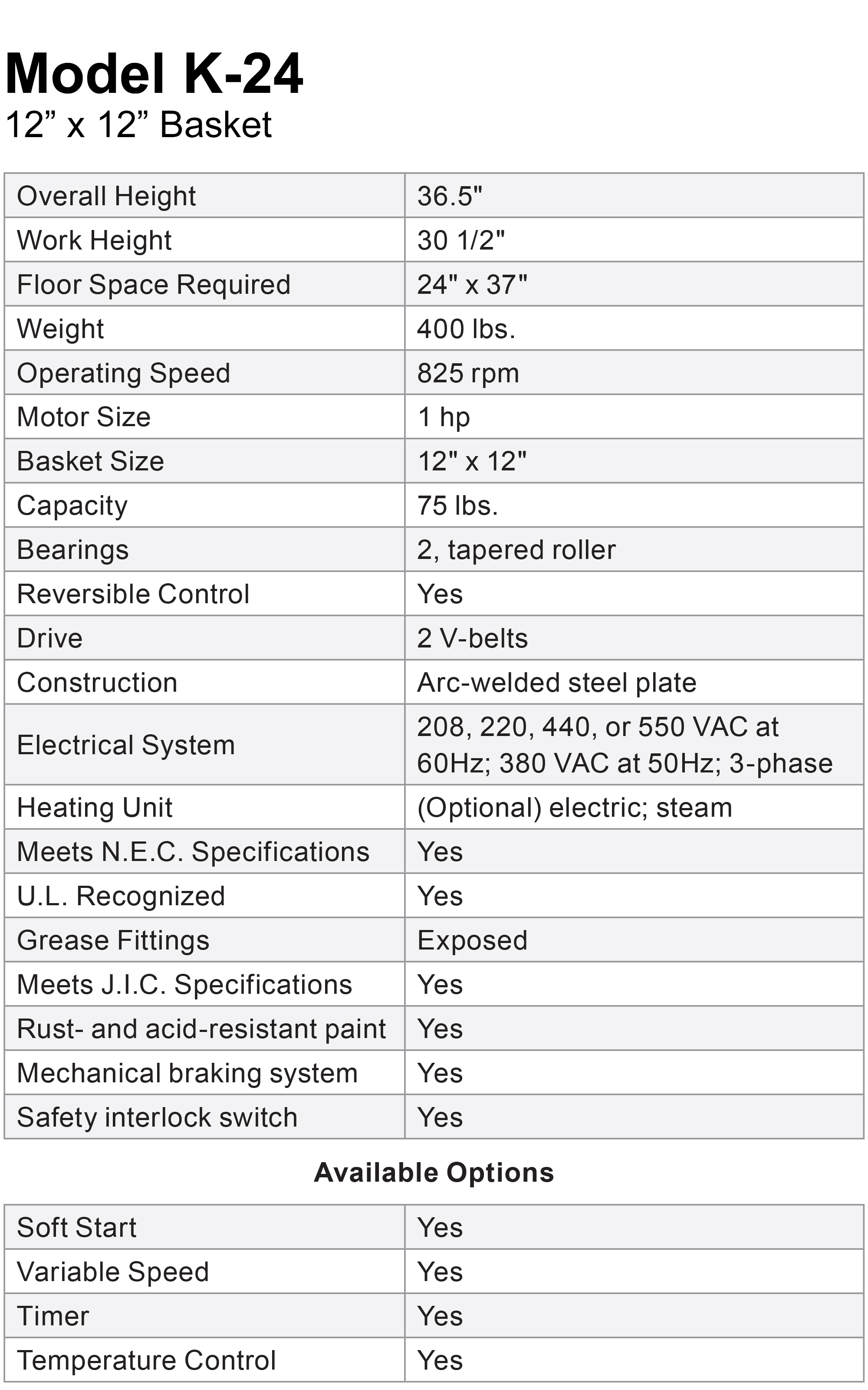

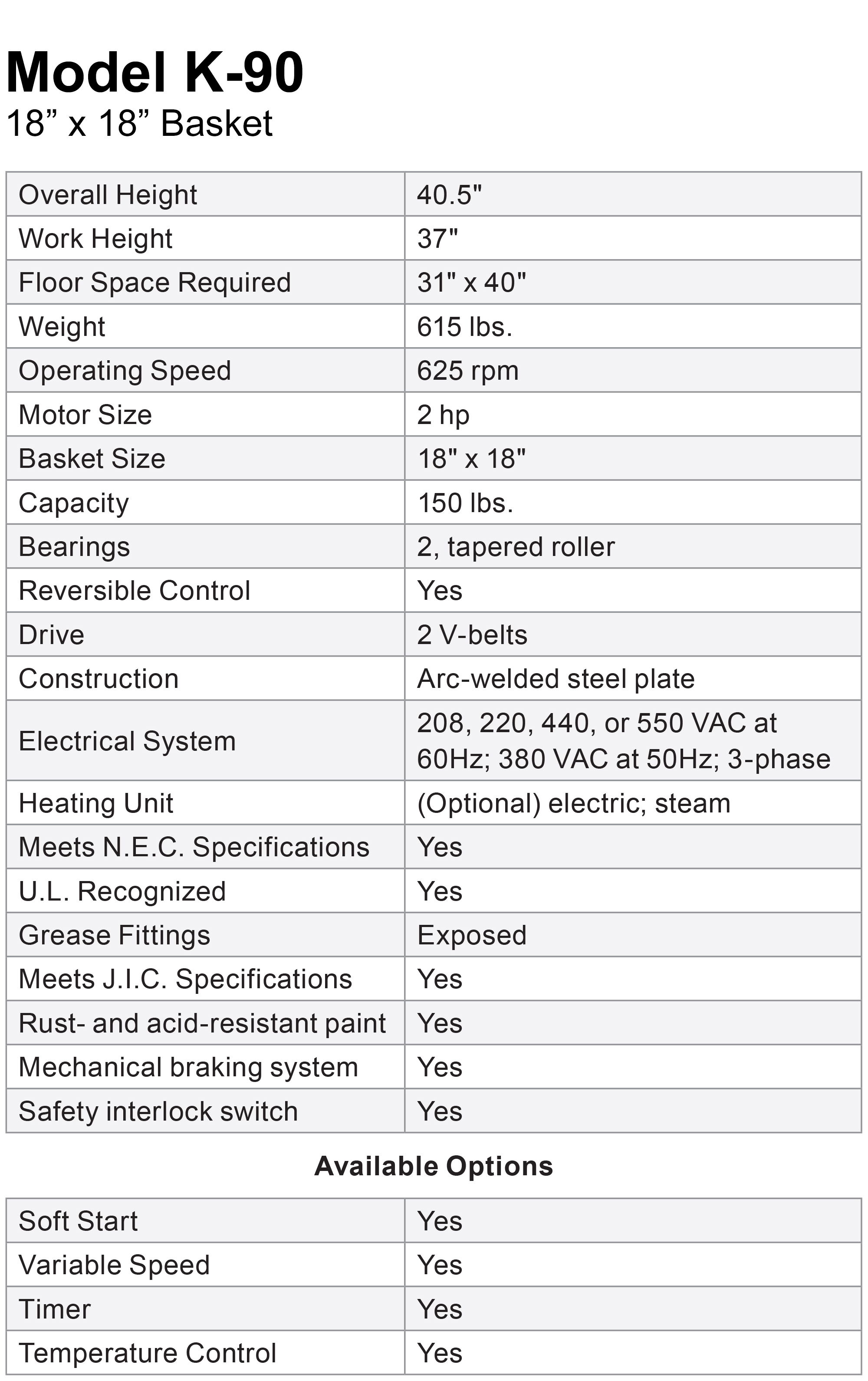

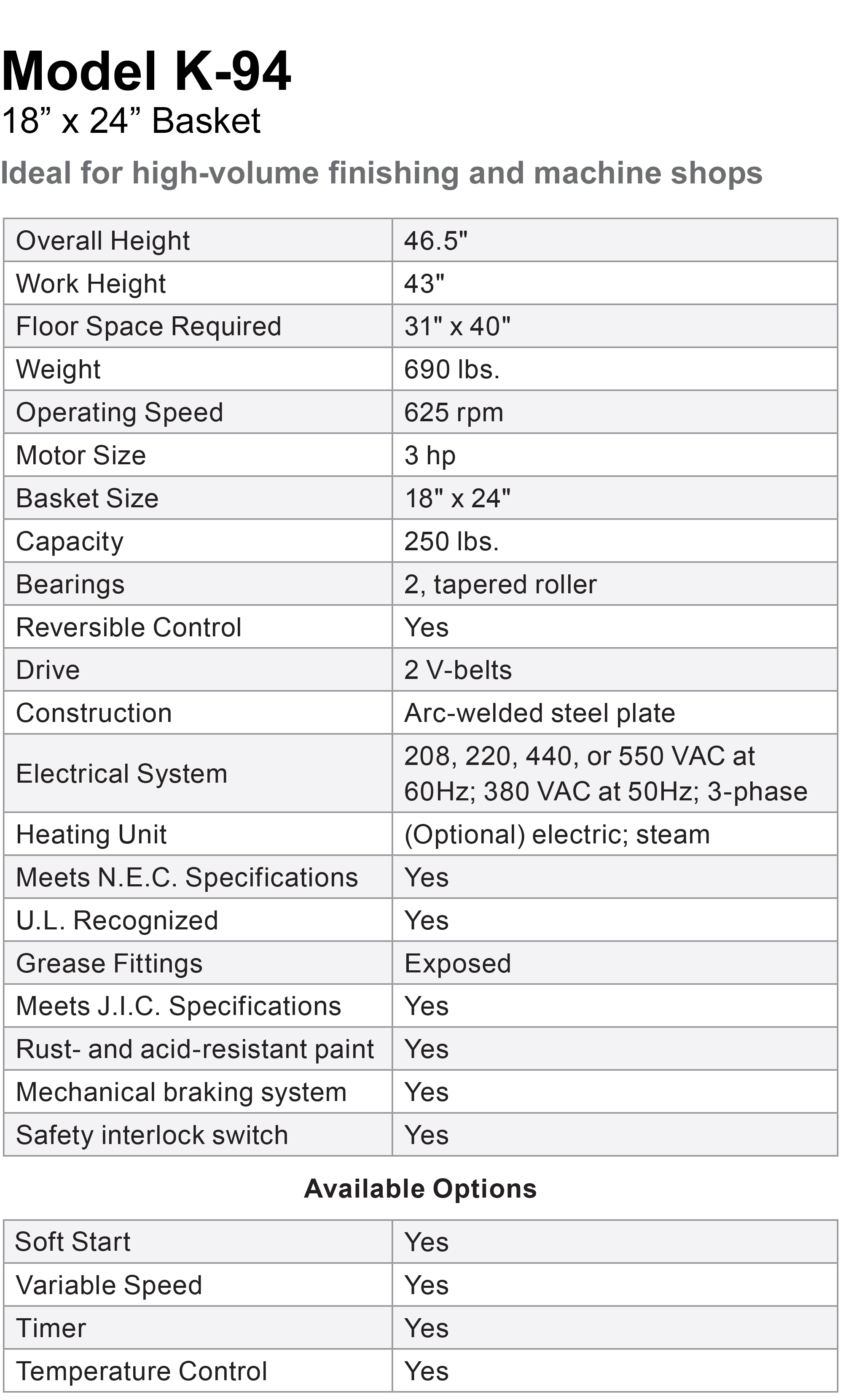

For specifications for each of the standard centrifugal dryers, please scroll down or select the model from the menu at the upper right corner of this page. Note that dimensions refer to basket size in inches (diameter x height).

• Soft Start provides a smooth, stepless, reduced-voltage acceleration of the parts load to minimize scarring and scratching of delicate parts. You simply adjust the initial torque and timing of the Soft Start to fit your needs.

• Variable speed permits reduced-speed operation to minimize damage to sensitive parts

• Timer assists the operator in controlling the time of the complete drying cycle

• Temperature control maintains heating within a controlled range for parts that are sensitive to excess heating